“ GS Press is a SKF recommendation Press Unit for heavy duty and long lasting bearing life”

- Manufactured and Assembled in Malaysia

- Engaging SKF Bearing Specialist,

- SKF designed bearing locations for proper bearing loading

- Working closely with experience Palm Oil Mill Engineers through R&D

BENEFIT:

- Heavy-duty press casing for shock loads and distortion free frame.

- Split type press casing for easy maintenance.

- Large cover for bearings inspection

- Separate location of spur gears for contamination-free bearings section

- Wobble free, stronger drive shafts to eliminate key-keyway, shaft failures.

- SKF designed bearing locations for proper bearing loading

- Higher duty thrust bearing for longer life

- SKF designed bearing housings with proper clearances

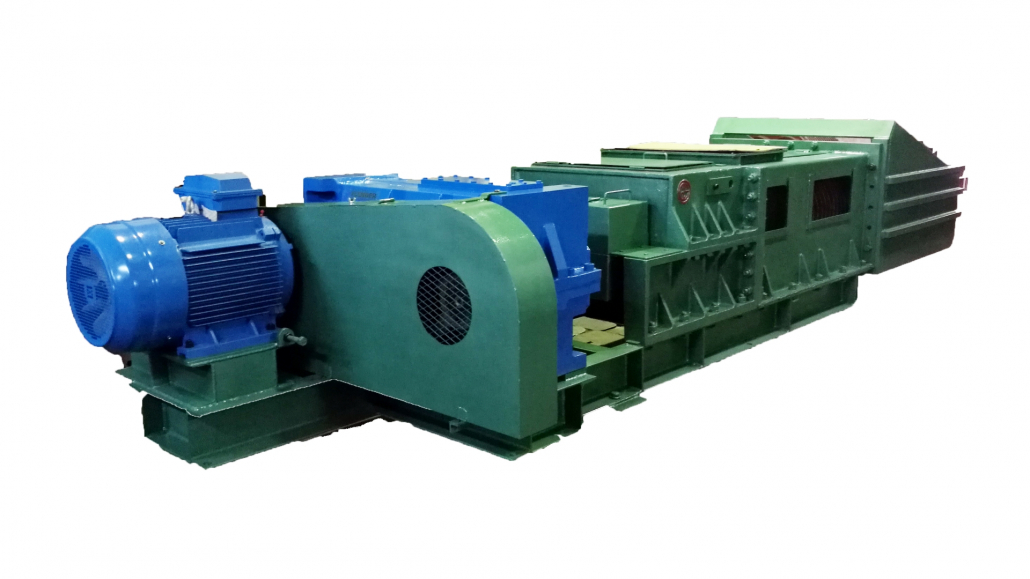

Specification

| GS P15 | GS P25 |

| Capacity : 15 – 17 tons FFB per hour

Type : Horizontal Twin Worm Screw Overall Dimension : 990 mm width X 630 mm height X 4600 mm long Weight : 4600 kg Speed : 9 – 13 rpm Power : 30 Kw Reducer : SEW EURODRIVE – M3PSF 50 SPD ( Best Selling Gearbox for Press Machine ) ratio 56/1 or (78/1) or equivalent – Included. Torque : 40,400Nm. Mechanical Power : 83 Kw ( at 1500 rpm ) Service Factor : 2.7 Output shaft diameter : 150 mm Material USED Press body : M.S/S.S Worm screw : Cast steel Hardened Press cage : M.S Strainer : S.S Main shaft : EN 24 Spur Gear : En9 With Heat Treatment |

Capacity : 20 – 25 tons FFB per hour

Type : Horizontal Twin Worm Screw Overall Dimension : 1250 mm width X 933 mm height X 5800mm long Weight : 6500 kg Speed : 8 – 10 rpm Power : 45 Kw Reducer : SEW EURODRIVE M3PSF 60 SPD( Best Selling Gearbox for Press Machine ) ratio 78/1 or equivalent – Included. Ratio : 77.373 Service Factor : 2.7 Output shaft diameter : 150 mm Material USED Press body : M.S/S.S Worm screw : Cast steel Hardened Press cage : M.S Strainer : S.S Main shaft : EN 24 Spur Gear : En9 With Heat Treatment |

Performance

| GS P15 | GS P25 |

| Operating Ampere : 33 A – 35 A

Oil loss on Non Oil Solid : 6.5% – 7.5% Nut and Kernel Breakage : 7% – 8% *The extend of oil loss and nut breakage depends on the type of FFB, quality of ripeness , sterilization, and digesting. |

Operating Ampere : 49 A – 51 A

Oil loss on Non Oil Solid : 6.5% – 7.5% Nut and Kernel Breakage : 7% – 8% *The extend of oil loss and nut breakage depends on the type of FFB, quality of ripeness , sterilization, and digesting. |